Name: Ivy Yang

Tel: +86 0731 22160466

Fax: +86 0731 22160196

Mobile: wechat/whatsup ID +86 18107334899

E-mail: sales@upcarbide.com

E-mail: ivy@upcarbide.com

Add: No.849,Hongqi North Road,ShiFeng District,Zhuzhou City,Hunan Province,China. post code 412000

Skype: ivyyang316

MSN: yangjuan316@hotmail.com

QQ:

2498362811

|

Product name : tungsten carbide composite brazing rod

Product No. : 2015611153022

|

| Details: | ||||||||||||||||||||||||||||||||||||

tungsten carbide composite brazing rod

tungsten carbide composite brazing rod A.tungsten carbide brazing rods they are made of by sintering tungsten carbide scrap and elastic matrix alloy,Outer layer of the special flux and coloring is marking scrap grade,the composition of sintering tungsten carbide scrap is mainly CO and WC,The hardness is HRA 89~91,tire body matal is Ni and copper alloy,strength can up to 690MPa, hardness HB≥160.

B. we can product 200kg witin 7~10 days

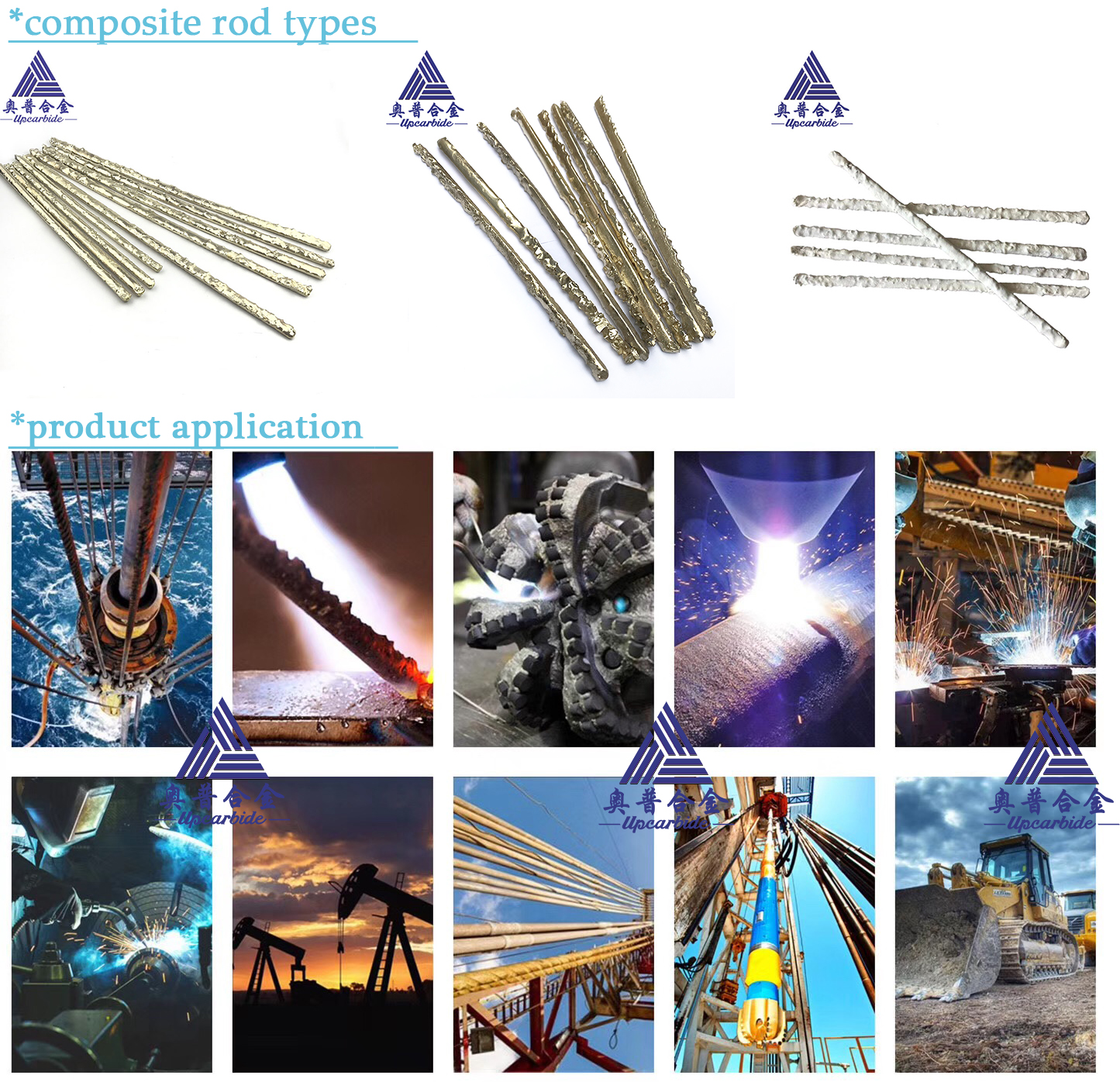

c. tungsten carbide brazing rods usage:

it is mainly used for surfacing welding the oil, mining, coal mining, geology, construction and other industries

D. tungsten carbide brazing rods size and grade:

there are eight grades according the size of tungsten carbide scrap.

E. overlaying process of tungsten carbide brazing rods,

The oxyacetylene butt, the operating process is as follows:

|

| Related Products : |

tungsten carbide needle

tungsten carbide needle

cast tungsten carbide

cast tungsten carbide