Name: Ivy Yang

Tel: +86 0731 22160466

Fax: +86 0731 22160196

Mobile: wechat/whatsup ID +86 18107334899

E-mail: sales@upcarbide.com

E-mail: ivy@upcarbide.com

Add: No.849,Hongqi North Road,ShiFeng District,Zhuzhou City,Hunan Province,China. post code 412000

Skype: ivyyang316

MSN: yangjuan316@hotmail.com

QQ:

2498362811

|

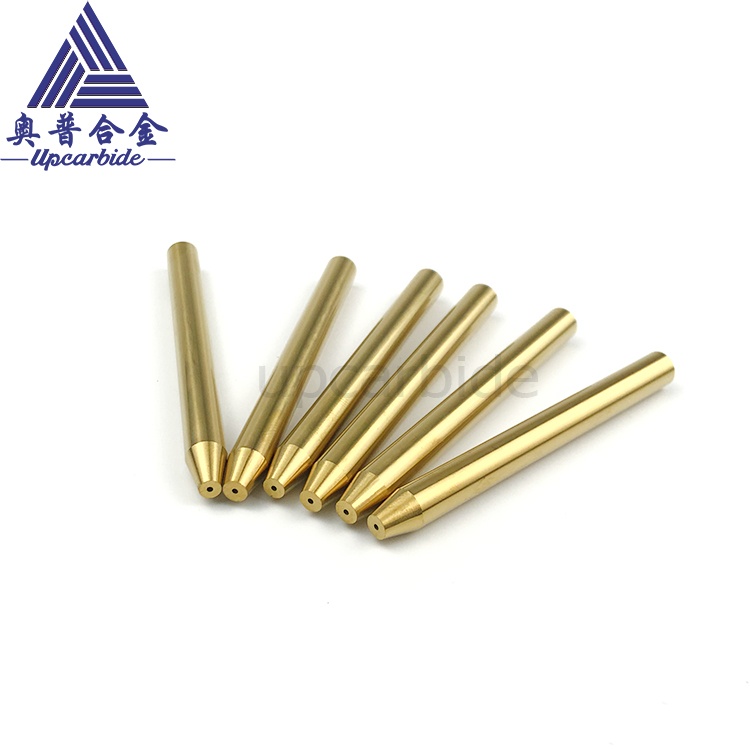

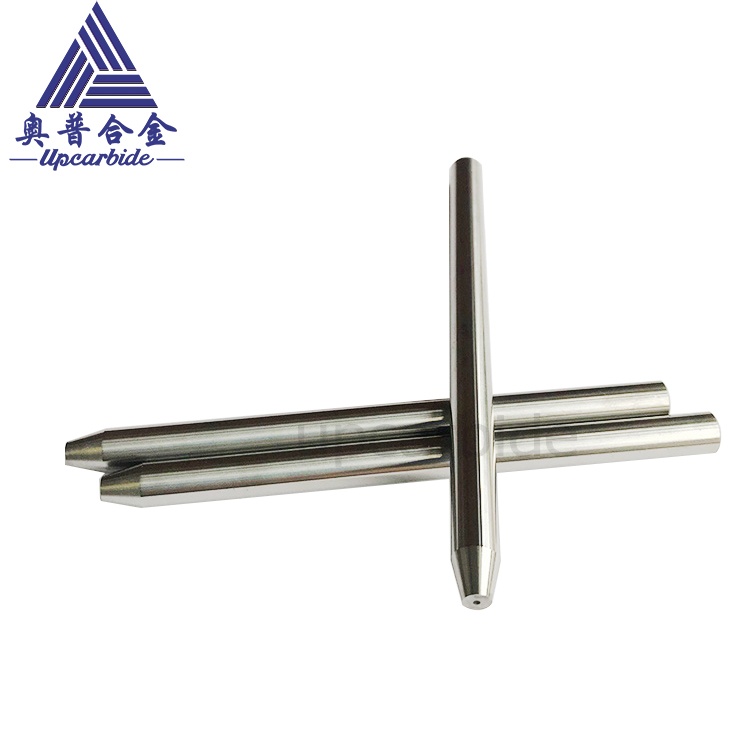

Product name : 1.02*7.14*76.2mm gold coated tungsten carbide waterjet spray nozzles

Product No. : 1.02*7.14*76.2mm

|

| Details: | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1.02*7.14*76.2mm gold coated tungsten carbide waterjet spray nozzles

1.02*7.14*76.2mm gold coated tungsten carbide waterjet spray nozzles tungsten carbide water-jet nozzle,also name tungsten carbide water cutting,tungsten carbide sand tube.it is mainly using to cutting metal,ceramic,stone,glass or other materials. 1.100% fresh material,we also coating tantalum tin for higher wear resistance.

2. the common sizes are Φ6.35,Φ7.14,Φ7.6,Φ9.45 ect.

3. long life,the hardness up to 96.5HRa,execellent wear resistance.

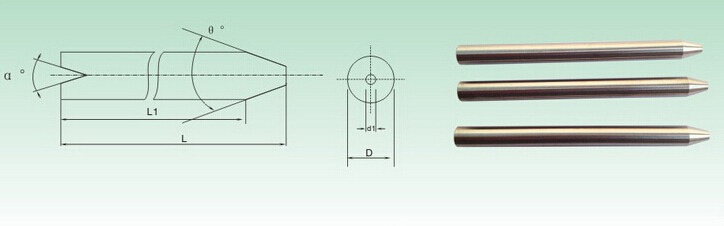

4. also product according your sizes. tungsten cabride water-jet nozzle‘s spcifications: Use superfine nanometer tungsten carbide particles, the wear-resisting performance to the next level, superior wear resistance makes it far beyond the ordinary tungsten carbide,The service life of the nozzle.Cobalt content of less than 0.6%, density of 15.45 g/cm3 ~ 15.6 g/cm3, bending 2000 mpa to 2400MPa.Super oxygen resistance, small thermal expansion coefficient, unique high hardness and density, far beyond the other similar products, the use of hard Alloy tube abrasion resistance stronger. Sand tube due to high-speed abrasive particle erosion, its selection is very important.Sand tube material, in general, must have high hardness, high resistance Grinding, both be short of one cannot.Generally for tungsten carbide composite materials processing.Usually, cemented carbide, WC as the main resistance,Grinding phase exists in the form of particles, CO, just as the binder. Use: widely used in various types machine, WHP type, FLOW type, type JET, KMT, OMAX type, type WS. tungsten carbide water-jet nozzle's common sizes:

|

| Related Products : |

tungsten carbide needle

tungsten carbide needle